Polybutylene (Poly B) piping was once considered the future of plumbing, offering a cheaper and seemingly efficient alternative to traditional copper pipes. However, its legacy has been tarnished by controversy and widespread failures, leading to its fall from grace. In this article, we’ll delve into the complete history of Poly B piping, its rise to popularity, the problems that emerged, and what homeowners should know about Poly B piping replacement.

What is Poly B Piping?

Poly B piping is a form of plastic piping that was made from polybutylene resin. It was developed in the 1970s and became a popular material for plumbing systems in residential properties across North America. These grey, flexible plastic pipes were used extensively from the late 1970s until the mid-1990s due to their low cost and easy installation.

Characteristics of Poly B

Poly B pipes are typically grey, flexible, and sometimes feature a blue or black hue. They come in various sizes and were commonly used for both indoor water distribution systems and as the main supply line to homes.

The Rise of Poly B Piping

Poly B was initially hailed as a revolutionary product. Its cost-effectiveness and flexibility made it a preferred choice for builders and homeowners looking to save on construction and renovation costs.

Why Poly B Became Popular

- Affordability: Poly B was much cheaper than copper and was marketed as being just as durable.

- Flexibility: Its flexibility meant it was easier and less labor-intensive to install than rigid copper piping.

- Resistance to Corrosion: Unlike copper, Poly B was not susceptible to corrosion, which was a significant selling point for areas with acidic water.

The Fall of Poly B Piping

Despite its initial popularity, the use of Poly B began to decline in the 1990s after numerous reports of pipe failures in homes. These failures often resulted in costly damage, leading to a loss of confidence in the material.

The Problems with Poly B

Failures were often attributed to the following factors:

- Oxidative Degradation: Exposure to chlorine in the water supply could cause the pipes to become brittle and crack over time.

- Poor Installation Practices: Incorrect installation, such as over-tightening fittings, could lead to leaks.

- Heat Exposure: Poly B did not perform well when exposed to high temperatures, which could lead to warping and damage.

- Degradation from UV Light: If Poly B was exposed to sunlight before installation, UV light could degrade the material.

The Aftermath: Lawsuits and Reputational Damage

A class-action lawsuit in the United States during the 1990s resulted in a settlement for homeowners with Poly B plumbing, and the reputation of Poly B was irreparably damaged. This led to the eventual discontinuation of Poly B piping.

Poly B Piping Replacement

For homeowners who still have Poly B piping in their homes, it’s crucial to consider replacement to prevent potential water damage from pipe failures.

Signs You Need Poly B Replacement

- Visible Signs of Degradation: Look for signs of flaking, brittleness, or discoloration on the pipes.

- Leaks: Even small leaks can indicate that the Poly B piping is failing.

- Age of the Pipes: If your home was built between the late 1970s and the mid-1990s, it’s worth checking to see if Poly B was used.

The Replacement Process

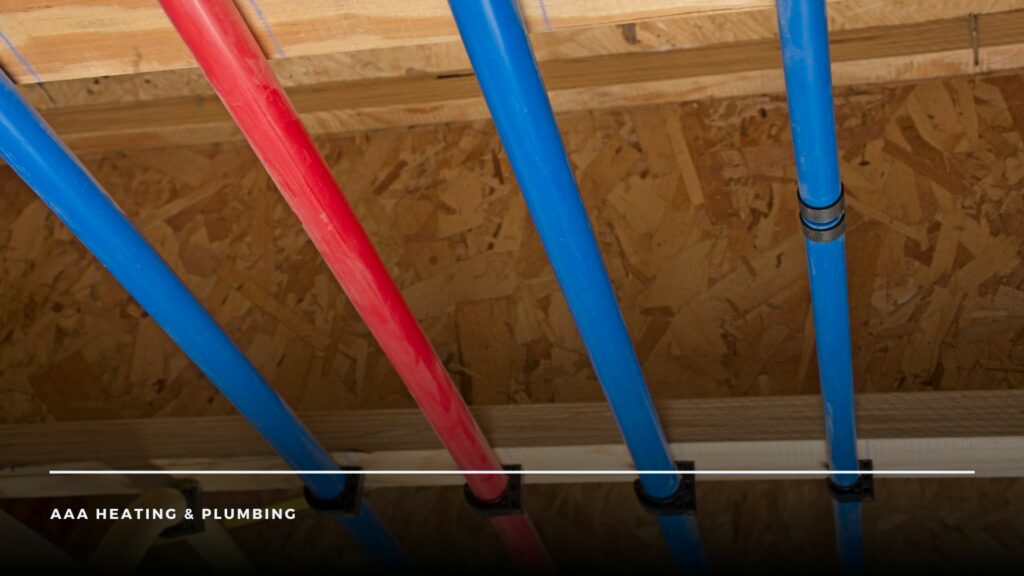

Replacing Poly B piping involves removing the existing pipes and installing new plumbing, typically using materials like copper, PEX, or CPVC, which are known for their durability and reliability.

The Legacy of Poly B Piping

The story of Poly B is a cautionary tale about the importance of long-term testing for building materials. While it offered short-term benefits, the long-term consequences have been a headache for many homeowners.

Lessons Learned

- Importance of Material Testing: Thorough and long-term testing is critical to ensure the durability and safety of construction materials.

- Awareness for Homeowners: Homeowners should be aware of the materials used in their homes and their potential risks.

- Proactive Replacement: Taking proactive steps to replace risky materials can prevent costly damage in the future.

Frequently Asked Questions About Poly B Piping

Is Poly B the Same as PEX?

No, Poly B and PEX (cross-linked polyethylene) are different materials. PEX has become a popular replacement for Poly B due to its improved durability and resistance to chemical and heat-related failures.

Can Poly B Pipes Last?

While some Poly B plumbing systems have lasted for decades without issues, the risk of failure increases with time. Replacing Poly B is recommended to mitigate the potential for leaks and water damage.

Does Poly B Affect Home Insurance?

Yes, some insurance companies may increase premiums or refuse coverage for homes with Poly B plumbing due to the high risk of water damage. Check with your insurer to understand their policy on Poly B.

How Much Does It Cost to Replace Poly B Piping?

The cost of replacing Poly B piping can vary depending on the size of the home and the complexity of the plumbing system. It’s best to get several quotes from reputable plumbers to understand the potential cost for your specific situation.

Poly B: Final Thoughts

Poly B piping serves as a reminder that new technologies must be vetted for longevity and safety. While it’s not a cause for immediate panic, homeowners with Poly B should consider replacement to prevent the possibility of future plumbing failures. By understanding the history and the risks associated with Poly B, homeowners can make informed decisions about their plumbing systems and ensure the safety and integrity of their homes.

The history of Poly B piping is a complex one, shaped by initial promise and subsequent disappointment. For those living with Poly B, the past may hold cautionary lessons, but it’s the future actions—such as timely replacement—that will ultimately protect their homes and investments.